notedwhenansweringaquestionabout thepipes

productionplan for2014.

A slab isa rectangularbilletmadebyacontinuous

castingmethod tobe further re-rolled intoafinished

product, etheraplateoracoil.Until recentlyRussian

slabproductionhasbeenmostlyexportoriented.

Cooperationbetween the two steel companies freed

frombroadplates import, considerably improved

logisticsandproductionatdomestic steel and tubes

companiesensuringpermanentlyhighquality

ofproducts for theoil andgascomplexdue toa

comprehensivecontrol at all theproduction stages.

“Ourcooperationestablished lastAugusthas

helpedus solve themostpressingproblem freeing

Russian tubescompanies fromplate imports.We

haveestablishedahigh-technologybigdiameter

pipesproductionchain: from ironoreexcavationand

steelmaking topipesmanufacture.Thishasbecome

possibledue toNLMKandOMKmultibillion-ruble

investments in technicalmodernization. Inmybelief,

out futurepartnershipwill becomeabenchmark in

thedevelopmentof thewhole industry strengthening

OMK’s leadership in theworld tubesandpipes

market andhelpingNLMKGroup tobecomea

leader in the suppliesof steelproducts for the tubes

andpipes segment”,O.Bagrincommentedon the

agreement achieved.

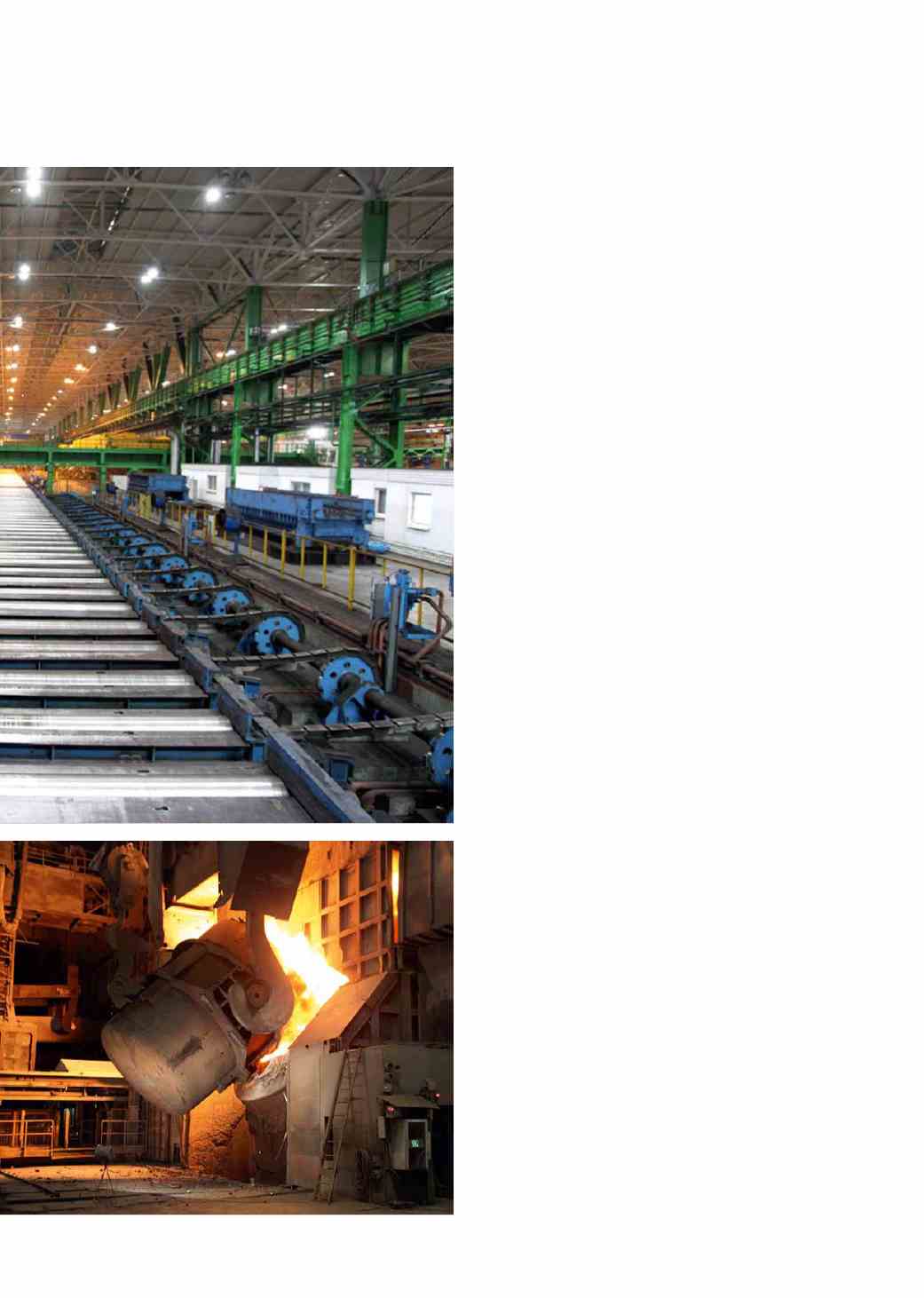

TheHeavyPlatesMill-5000also rolls slabs

250mm thick, 1400—2200mmwide, 355mm thick,

1700—2200mmwide, and310mm thick, 1700—

2200mmwide.NLMK is theonlyRussianproducer

manufacturing slabs355mm thickand2200mm

wide.Afterconvertermeltingall the steelmade for

Vyksafirstgoes to the ladle-furnace for treatment,

then to theRHunit fordegassing tobe followed

bypouring into slabsmainlyat continuouscasting

plant№8.All theseplantsandunitswerebuiltor

modernized in thecourseof the second stageof the

implementationof theprogramon the technical

modernizationof themainNLMK facilities in

2010—2012.

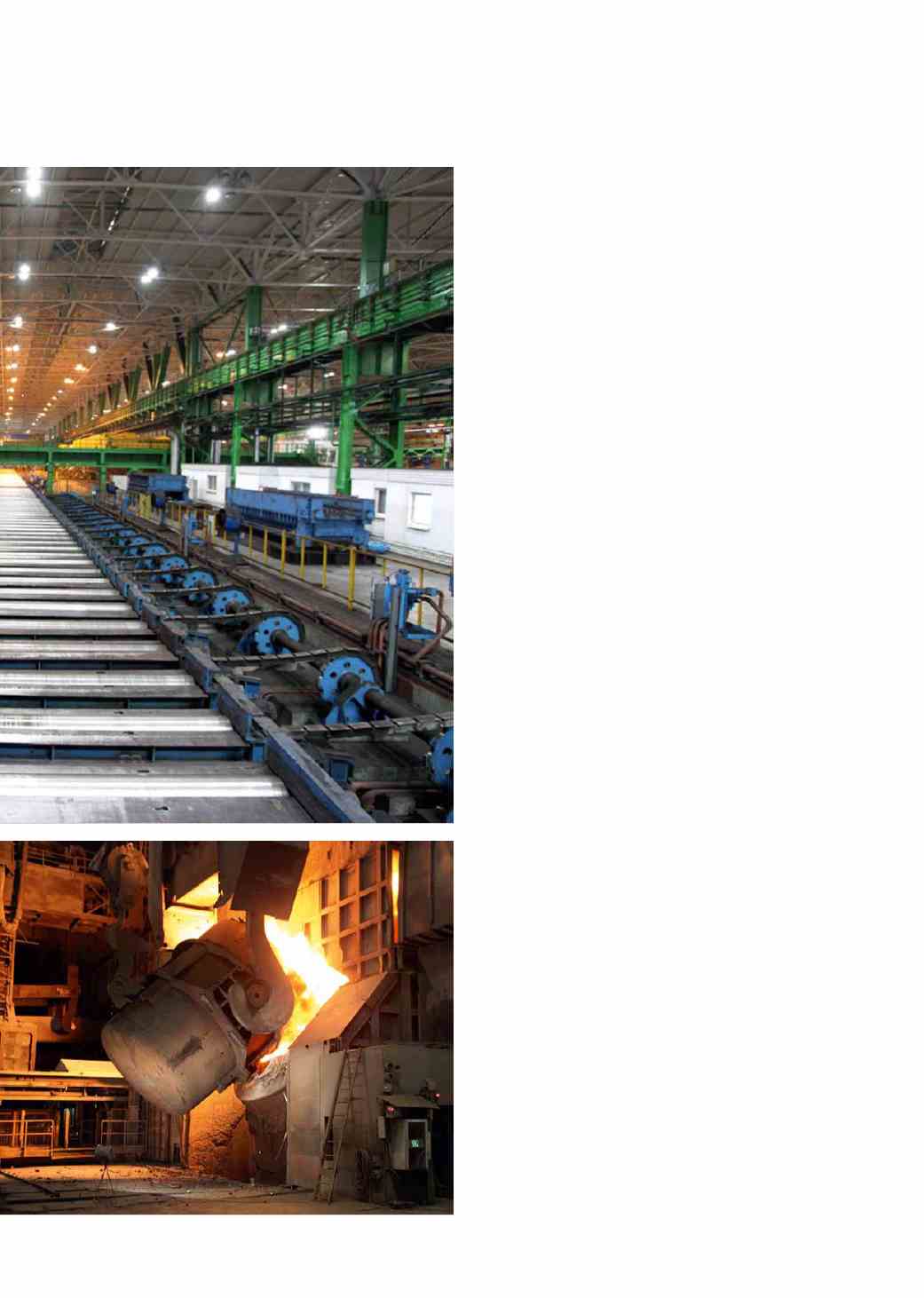

In the recent yearsdue tomodernizationofold

andcommissioningofnew facilitiesNLMKhas

considerably improved itsout-of-furnace steel

treatment.TodayLipetskoperates four ladle-furnace

unitswith the total capacityof12Mt/y, ten ladlefinal

separationunits, twoRHunitswith thecapacityof

400kt/y in theconverterplant№1and thecapacityof

4Mt/y in theconverterplant№2 (commissioned in

September2011).

VyksaSteelWorksproduced1.285Mtofbig

diameterpipes in2012—2013 forbigRussian

and internationalpipelineprojects including

Bovanenkovo—Ukhta,Ukhta—Torzhokby

Gazprom,Zapolyarye—PurpebyTransneft, building

of the third lineofMiddleAsia—Chinapipelineand

manymore.

L

ReviewbyMaximLobada.

Special Issue 2014

Metal Supply&Sales